Everything About Oil Field Equipment and Pipeline Equipment: Secret Insights and Important Details

Oil field equipment and pipeline systems play a critical function in the oil and gas market. They are necessary for the reliable extraction and transport of hydrocarbons. Secret components, such as piercing rigs and tank, directly impact functional success. At the same time, innovations in modern technology promise to improve security and effectiveness. Recognizing these elements is vital for anyone associated with or thinking about this complicated market, as it sets the phase for deeper exploration of market techniques.

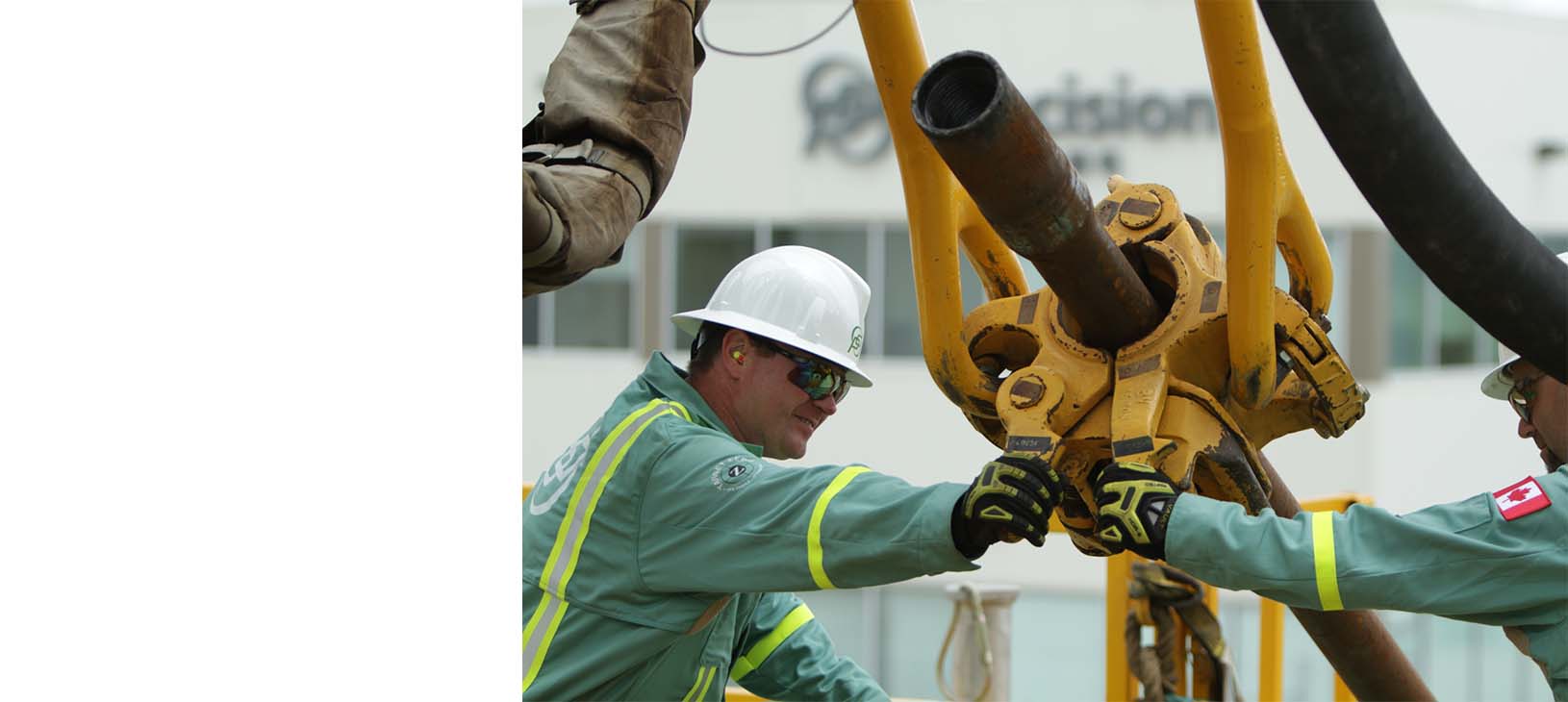

Summary of Oil Field Equipment

As the demand for oil proceeds to grow, comprehending the equipment made use of in oil fields comes to be increasingly crucial. Oil field equipment encompasses a vast array of machinery and tools vital for exploration, extraction, and processing. Trick elements include drilling rigs, which are important for getting to oil storage tanks, and production equipment, such as separators and pumps, that facilitate the removal process. Superior Rentals fusion machines. Furthermore, storage containers play a considerable role in holding petroleum prior to transport. Safety and security equipment, including blowout preventers and stress assesses, guarantees functional safety and efficiency. Each piece of tools functions cohesively to optimize production and keep efficient operations. Knowledge with this equipment is essential for specialists in the market to assure successful procedures and adherence to security requirements

Types of Drilling Rigs and Their Applications

Drilling rigs act as the foundation of oil extraction procedures, with different kinds created for specific geological problems and functional needs. The most usual types include rotary exploration rigs, which utilize a turning drill little bit to penetrate the earth, and cord device rigs, recognized for their percussion exploration method. For overseas procedures, jack-up rigs and semi-submersible rigs provide stability and support in aquatic atmospheres. Additionally, directional boring rigs allow operators to drill at angles, reaching down payments that are not vertically available. Each rig kind has one-of-a-kind benefits, maximizing effectiveness and safety based upon the boring setting. Picking the proper rig is essential for making the most of resource removal while lessening ecological influence and functional costs.

Crucial Pipeline Equipment and Their Features

Pipeline infrastructure is vital for the transport of oil and gas from extraction sites to processing facilities and end-users. Different crucial tools parts facilitate this procedure. Pipelines themselves act as the primary conduits, made to hold up against high pressure and destructive compounds. Pump terminals are vital for preserving flow by increasing stress along the pipeline. Valves play a vital duty in regulating circulation and isolating sections for upkeep. Additionally, fittings and adapters ensure secure joints between pipeline areas. Checking systems, consisting of circulation meters and pressure sensing units, are crucial for identifying leakages and enhancing flow rates. Finally, pigging devices is used for upkeep and cleaning, safeguarding pipeline honesty and effectiveness. With each other, these elements create the backbone of a trustworthy pipeline system.

Advancements and Technologies in Oil and Gas Equipment

Security and Upkeep Practices in the Oil Sector

While the oil market has made significant strides in modern technology and performance, the significance of robust security and maintenance practices can not be overstated. Reliable security methods are vital to protect workers and the atmosphere, decreasing the threat of accidents and spills. Normal inspections and maintenance of devices assistance determine prospective issues before they intensify, making sure operational integrity. Educating programs for staff members are vital, emphasizing the significance of safety and security understanding and emergency feedback procedures. In addition, adherence to sector guidelines and standards promotes a culture of security. Applying sophisticated monitoring innovations can additionally enhance upkeep techniques, enabling real-time evaluations of devices problems. Inevitably, focusing on safety and maintenance is indispensable to the sustainability and success of the oil sector.

Often Asked Inquiries

What Are the Environmental Influences of Oil Field Equipment?

The environmental effects of oil field equipment include environment devastation, water contamination, and air contamination (Superior Rentals midland). Additionally, tools breakdown can cause spills, negatively affecting wild animals and ecological communities, highlighting the demand for rigorous laws and surveillance

How Is Oil Field Equipment Moved to Remote Locations?

Transporting oil field equipment to remote locations commonly entails customized lorries, helicopters, or barges. Logistics business coordinate paths, making certain devices shows up securely and effectively, taking into consideration terrain and ease of access to minimize delays and optimize efficiency.

What Governing Requirements Govern Oil Field Equipment?

Governing requirements controling oil field equipment mostly drain pipe replacement consist of safety, environmental defense, and operational effectiveness guidelines. Agencies such as OSHA and EPA enforce these guidelines to assure safe methods and reduce eco-friendly effect in oil extraction operations.

What Skills Are Required to Operate Oil Field Machinery?

Exactly How Do Oil Rates Affect Equipment Demand and Use?

Oil prices considerably influence devices need and use. Higher prices typically bring about enhanced exploration and production tasks, driving demand for machinery. Conversely, reduced prices may cause minimized operations and decreased demand for tools.